|

|

AUTOMATION SPECIALISTS |

|

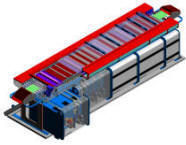

Conventional immersion chambers result from pumping fluid from a sump to a dammed roller conveyor chamber. The solution is re-circulated at a rate of approximately 5X VPM (chamber volume per minute) via manifolds positioned between the conveyor rollers to displace depleted chemistry and trapped gasses. This combination of flooded jet and roller wheel transport results in chaotic turbulent zones within a stagnant bath. By contrast, Streamline Fluid Engine immersion chambers have no rollers and provide laminar solution flow at a 100X VPM, resulting in faster, more uniform reactions.

|

|||||

|

Print friendly version in PDF format click here | ||||

|

Tin Stripping system | To download a brochure in PDF format click here | |||

|

Chemical Clean Surface Treatment system | To download a brochure in PDF format click here | |||

|

CharterSILVER Immersion Silver Processor Model BLT 500 |

To download a brochure in PDF format click here | |||

|

CO-BRA BOND

® Surface

Treatment system Model 1000 |

To download a brochure in PDF format click here | |||

|

SHADOW 750 ® Direct Metalisation System | To download a brochure in PDF format click here | |||

|

MECetchBOND Surface Treatment system Model MEC ™ 1000 |

To download a brochure in PDF format click here | |||

|

AlphaSTARTM

Immersion Silver Processor Model AS200 |

To download a brochure in PDF format click here | |||

|

OSP Surface Treatment system | To download a brochure in PDF format click here | |||

|

Compact Flat Belt Loader & Unloader | To download a brochure in PDF format click here | |||

Here is a narrated power point presentation entitled Saving Energy and Reducing Waste (file size 14 mb), which explains the developments made in the design of wet process equipment and the benefits of the new Streamline design.

Bruce Routledge published an article in The Journal of the The Institute of Circuit Technology (Oct 2009), a paper entitled "AN INNOVATION IN HORIZONTAL PROCESSING", click here to read in full.

A fast installation is what you will get with a Streamline

system.

The link below records an Immersion Silver line installation that took approx

4 hours (excluding connection to the utilities) from start to finish and

shows the system's unique construction compared to conventional wet process

systems. The upper conveyor/process chambers are completely separate to the

sumps and mounted on a stainless tubular frame. The benefit of having this type

of support frame is that it allows the system to expand and contract in a

straight line and thereby eliminating excess load on the drive motor.

Streamline system installation

OTHER FEATURES & BENEFITS

Here follows a sequence of video downloads which demonstrate the ease of maintenance with a Streamline system.

|

FILTER REMOVAL & CLEANING

|

DRYER

HEAD SEPARATION & CLEANING |

DRYER HEAD REMOVAL |

|

PUMP REMOVAL & REPLACEMENT |

STREAMLINE ENGINE SEPARATION &CLEANING |

SUMP REMOVAL |

|

STREAMLINE ENGINE REMOVAL & REPLACEMENT |

FLUID KNIFE SEPARATION & CLEANING |

FLUID KNIFE REMOVAL & INSERTION |