|

|

|

|

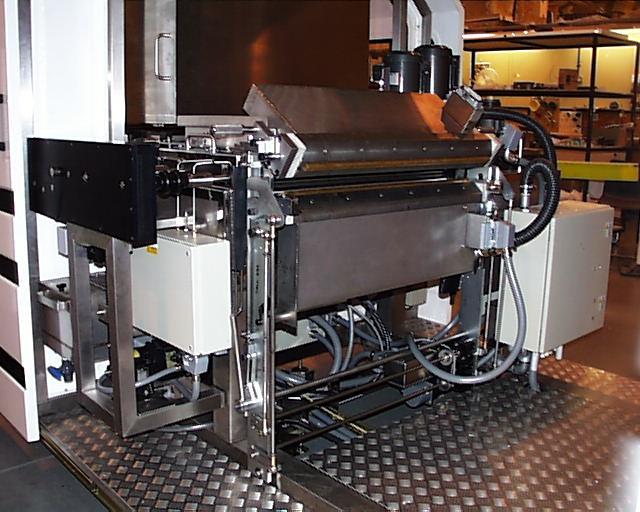

D type overview:

Front view showing control console in standard fixed

position. Panels feed left to right.

Left and right doors open for total access.

Front and rear doors open with the exit air table in the up position, allowing all round access to the solder sump, transmission and air knives.

Rear view showing optional cooling module at the Alchemy exit.

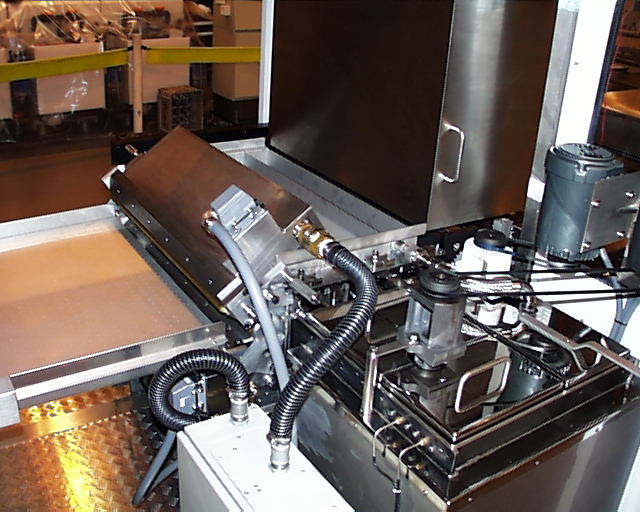

View of the roller drive transmission assembly. The inner canopy has been moved to the left, exposing the oil manifold assembly, providing access to the solder manifolds and transmission rollers.

Notice the upper and lower air knife adjustment linkage. This is connected to a servo drive motor for automatic adjustment of air knife offset and gap. The upper air knife hinges, permitting operator access for cleaning the upper and lower tips.

Complete solder coat section showing the exit air table in the operating position.

The exit air table comprises a stop gate, and a support roller/overhead air knife, which accelerates the panels into the post treatment system.

Rear view exposing the main auxiliary enclosures for

the air knives and sump heaters. The sump is

fitted with external heating elements. The

air knives have integral heat exchangers.

View of the solder/oil sump, including drives to the

oil and solder pumps (drive belt guards removed).

View of the upper air knife in the hinged position for cleaning.

Align/Rotate module. The panel is centralised across the conveyor prior to being raised and rotated at 45 degrees. An upper retaining pressure pad holds the panel securely during the rotate cycle.

ALCHEMY ‘D’ BENEFITS